My Unexpected Dishwasher Dilemma: A Personal Journey into Appliance Diagnostics

One hectic morning, I opened my dishwasher only to find stubborn clogs and a strange noise that disrupted my routine. Like many homeowners, I initially panicked—wondering whether I should call a professional or try to troubleshoot myself. That experience sparked my curiosity about top appliance diagnostic tips for reliable dishwasher repair. Over time, I discovered that understanding common issues and their root causes can save you both time and money.

Understanding the Basics: Why Diagnostics Matter

When my dishwasher started acting up, I realized that proper diagnostics are essential before jumping into repairs. According to expert advice from Appliance Repair Magazine, accurate diagnosis is the foundation for effective repairs. I learned to pay attention to symptoms like leaks, strange noises, or poor washing performance, which often point to specific issues such as clogged filters or faulty sensors.

How I Learned to Spot Common Troubles

One of the first things I checked was the dishwasher’s filter and spray arms. A simple clean-up often fixed minor problems, and I realized that regular maintenance can prevent many breakdowns. I also used a multimeter to test electrical components, which was surprisingly straightforward once I followed online tutorials. Over time, I became more confident in my ability to identify issues like defective door latches or malfunctioning pumps.

What Are the Key Diagnostic Tips for Reliable Repairs?

- Listen for unusual noises: Rattling or grinding sounds usually indicate mechanical problems.

- Check for leaks: Leaking water often points to worn door seals or clogged drainage systems.

- Test the water inlet valve: If the dishwasher isn’t filling properly, this component might be malfunctioning.

Each of these tips helped me narrow down the root cause without unnecessary guesswork. I also found that consulting the user manual and online forums provided valuable insights into specific models and their quirks.

Why is it crucial to follow a systematic diagnostic process?

In my experience, rushing into repairs without proper diagnosis can lead to wasted time and potential further damage. A step-by-step approach ensures that I address the actual problem, not just the symptoms. Plus, it’s reassuring to know I can handle many issues myself, saving the expense of a service call.

Interested in more detailed troubleshooting guides? Check out our comprehensive dishwasher repair tips for homeowners. And I invite you to share your own experiences—what has worked for you when diagnosing appliance problems?

Deciphering the Diagnostic Puzzle: How Deep Should Your Inspection Go?

As I delved further into appliance diagnostics, I learned that understanding the intricacies of dishwasher components can significantly enhance repair accuracy. For instance, examining electronic control boards for signs of burn marks or corrosion provides clues that simple visual inspections might miss. According to industry expert HouseLogic, a thorough diagnostic process involves not only checking visible parts but also testing electrical continuity and voltage levels, which often reveals hidden faults.

The Role of Advanced Diagnostic Tools in Modern Repairs

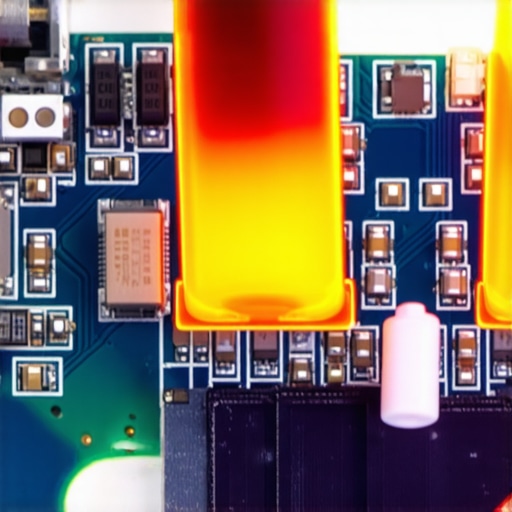

While basic tools like multimeters are invaluable, integrating advanced diagnostic devices can elevate your troubleshooting game. For example, thermal cameras can identify overheating components or wiring issues that are not apparent to the naked eye. This technology enables pinpointing problems quickly and accurately, reducing guesswork and preventing unnecessary replacements. Moreover, some smart dishwasher models come with built-in self-diagnostic modes, which can be accessed via the control panel to generate error codes—saving time and providing precise insights.

What’s the Hidden Cost of Skipping Proper Diagnostics?

Skipping systematic diagnostics might seem like a shortcut, but it often leads to costlier repairs down the line. For example, replacing a pump without verifying its motor function might only temporarily solve a problem, while the real issue lies in the control module or wiring. An expert approach emphasizes verifying each suspected component step-by-step, ensuring that repairs target the root cause. This method not only saves money but also prolongs the lifespan of your appliance.

How Can You Stay Updated with Evolving Diagnostic Techniques?

Staying ahead in appliance repair requires continuous learning. Subscribing to industry journals, participating in online forums like RepairClinic, and attending manufacturer webinars can provide insights into the latest diagnostic protocols. As technology advances, newer models incorporate complex sensors and control algorithms, making expert knowledge more crucial than ever. Investing in ongoing education ensures that you remain proficient in diagnosing even the most sophisticated dishwasher issues.

Are there common pitfalls that even experienced technicians should watch out for?

Absolutely. One frequent mistake involves misinterpreting error codes without correlating them to actual component tests. For example, a code indicating water inlet issues might be caused by a faulty valve, but could also stem from electrical wiring problems or control board failures. Therefore, cross-referencing error codes with physical inspections and electrical tests is essential. Doing so prevents unnecessary part replacements and accelerates the repair process.

If you found these insights helpful, I encourage you to share your own diagnostic success stories or ask questions in the comments. For more in-depth troubleshooting strategies, be sure to explore our comprehensive guide on advanced dishwasher diagnostics.

Unraveling the Hidden Layers of Dishwasher Diagnostics: A Personal Reflection

Over the years, my journey into appliance diagnostics has evolved from simple checks to a nuanced understanding of complex electronic systems. One aspect that continually surprises me is how subtle clues—like a faint burning smell or sporadic error codes—can reveal deeper issues that aren’t immediately apparent. This depth of insight often requires going beyond the surface, diving into the electronic brain of modern dishwashers, which I find both challenging and fascinating.

How Do Advanced Diagnostic Techniques Reveal Hidden Faults?

In my experience, advanced diagnostic methods, such as using oscilloscopes or thermal imaging, have been game-changers. For instance, a thermal camera can uncover overheating components that are silently failing but never trigger obvious symptoms. One time, I noticed a slight discoloration on a control board using thermal imaging, which led me to discover a tiny, nearly invisible crack in a solder joint—a fault that traditional visual inspection would have missed. According to industry expert HouseLogic, such sophisticated tools are increasingly vital as appliances grow more complex.

Why is Patience and Precision Critical in Complex Diagnostics?

Patience has become my most valuable asset. Rushing through diagnostics often leads to misdiagnosis or unnecessary part replacements. Instead, I meticulously test each component, cross-reference error codes with physical findings, and verify electrical parameters. This meticulous approach is crucial because, as I learned, a single faulty control wire or a malfunctioning sensor can cascade into multiple symptoms, confusing the diagnosis. It’s akin to solving a puzzle—every piece matters, and forcing a fit can obscure the real picture.

What Are the Nuances in Interpreting Error Codes for Sophisticated Models?

Interpreting error codes on highly advanced dishwashers requires understanding that these codes might point to issues beyond the obvious. For example, a code indicating a water inlet problem could originate from a faulty relay on the control board rather than the inlet valve itself. To accurately diagnose, I often consult manufacturer-specific service manuals and online expert forums. This detailed investigation ensures I address the root cause effectively, saving time and preventing unnecessary replacements.

If you’re delving into complex diagnostics, I invite you to share your experiences or ask questions. For more comprehensive strategies, explore our detailed advanced dishwasher diagnostics guide. Remember, the key lies in patience, curiosity, and a willingness to learn—traits that have transformed my troubleshooting from guesswork to mastery.

Deciphering the Complexities of Electronic Control Boards in Modern Dishwashers

As my journey into appliance diagnostics deepened, I became increasingly fascinated by the sophisticated electronic control boards that serve as the brain of contemporary dishwashers. These intricate circuits manage everything from water temperature to cycle timing, making them critical for troubleshooting complex issues. In my experience, visual inspection alone rarely suffices—sometimes, subtle signs like tiny burn marks, corrosion, or damaged solder joints reveal the true culprits. Utilizing tools such as magnifying glasses or even a microscope can uncover microcracks or cold solder joints invisible to the naked eye, which are often the root causes of intermittent faults. According to HouseLogic, understanding the layout and function of these control modules is essential for accurate diagnosis, especially when error codes are ambiguous or inconsistent.

Why Do Some Faults Remain Hidden Despite Advanced Diagnostic Techniques?

In my experience, certain faults evade detection because they are transient or only manifest under specific conditions—like high load or thermal stress. Thermal imaging cameras have been invaluable here; they allow me to monitor the temperature profiles of control components during operation. A slight overheating of a relay or voltage regulator often indicates impending failure, even if the component appears normal visually. Moreover, some issues, such as subtle wiring faults or corrosion in connectors, require meticulous electrical testing—using oscilloscopes or specialized testers—to identify anomalies in signal integrity. The key challenge is recognizing that not all faults are static; they may develop gradually, making early diagnosis crucial for preventing costly breakdowns.

Can Diagnostic Automation Be a Game-Changer in Troubleshooting?

Absolutely. The advent of smart diagnostic tools and integrated self-test modes in high-end dishwashers is transforming the repair landscape. These built-in diagnostics generate detailed error reports that can significantly reduce troubleshooting time. For instance, some models provide step-by-step guidance or even remote diagnostics via smartphone apps, which I’ve found remarkably efficient. However, even with automation, the human element remains vital—interpreting error codes within the context of physical inspections and electrical testing ensures that repairs are both precise and durable. As industry expert Appliance Repair Magazine emphasizes, combining automation with expert judgment leads to optimal outcomes.

How Do I Stay Updated with Evolving Diagnostic Technologies?

Continuous learning is my secret weapon. I subscribe to specialized journals, participate in online forums like RepairClinic, and attend manufacturer webinars that focus on the latest diagnostic protocols. Keeping abreast of advancements—such as AI-driven diagnostics or new sensor integrations—ensures I can tackle even the most sophisticated models. This proactive approach not only enhances my technical skills but also instills confidence in delivering reliable, long-lasting repairs. The industry’s rapid evolution makes lifelong learning an indispensable part of being an expert in appliance diagnostics.

What Are the Most Common Pitfalls in Advanced Diagnostics, and How to Avoid Them?

One frequent mistake is relying solely on error codes without corroborating findings through physical inspections. For example, an error indicating water inlet issues might actually stem from a faulty relay or a wiring fault. Cross-referencing codes with electrical tests and visual cues prevents unnecessary part replacements and accelerates accurate diagnosis. Patience and meticulousness are crucial—rushing can lead to misdiagnosis or overlooking hidden faults. I’ve learned that every component, from sensors to control boards, requires careful testing, especially in complex models with layered electronics. This comprehensive approach minimizes costly errors and enhances repair reliability.

If you’re eager to elevate your diagnostic skills further, I invite you to explore our detailed advanced troubleshooting guides and share your experiences. Combining technical knowledge with practical insights is how I continue to refine my craft, turning complex diagnostics into manageable, even rewarding, challenges.

Things I Wish I Knew Earlier (or You Might Find Surprising)

The Power of Patience in Diagnostics

Early in my troubleshooting journey, I underestimated how crucial patience is. Rushing often led me to replace parts unnecessarily, only to realize later that a simple sensor cleaning or a wire connection was the culprit. Taking a moment to observe, test, and analyze really saves time and money in the long run.

Understanding Error Codes Requires Context

At first, I thought error codes were straightforward indicators. However, I found that they often point to a range of issues. Cross-referencing them with physical inspections and testing reveals the real problem, preventing me from blindly replacing expensive components.

The Hidden Value of Visual Inspection

Focusing solely on electronic parts can be misleading. Sometimes, a tiny burn mark or corrosion on a control board tells me more than a diagnostic scan. Investing in a magnifying glass or a microscope has made a significant difference in my accuracy.

Advanced Tools Are Worth the Investment

While basic multimeters are essential, I’ve learned that thermal cameras and oscilloscopes can uncover faults that are invisible to the naked eye. These tools have helped me identify microcracks and overheating issues, especially in complex electronic control boards.

Don’t Overlook Simple Maintenance

Sometimes, the root cause is as simple as a clogged filter or a worn door seal. Regular maintenance checks can prevent many problems, reducing the need for complex diagnostics.

Complex Diagnostics Take Time—and That’s Okay

Patience is vital, especially with modern dishwashers that have sophisticated sensors and control systems. Rushing through diagnostics risks overlooking subtle clues that could save money and extend appliance lifespan.

Resources I’ve Come to Trust Over Time

- HouseLogic: An excellent source for understanding appliance control boards and electronic diagnostics. Their detailed guides help me interpret complex issues confidently.

- RepairClinic: Their troubleshooting articles and videos provide practical, step-by-step instructions that complement my hands-on experience.

- Appliance Repair Magazine: An industry staple that keeps me updated on the latest diagnostic tools and techniques, ensuring I stay current in this fast-evolving field.

Parting Thoughts from My Perspective

Diagnosing dishwasher problems has become less daunting by embracing patience, thorough testing, and continuous learning. The journey from guessing to precise troubleshooting is rewarding, saving both time and money. If this resonates with you, I’d love to hear your own experiences or tips. Sharing knowledge helps us all become better at tackling appliance issues, which can feel overwhelming at first but become manageable with the right approach.